This is a little device I made that I call a Rolodex Mutoscope.

The Rolodex was a ubiquitous late 20th-century piece of office equipment used to store business contact information on card stock. The Mutoscope was an early motion picture device from the late 1800s that was basically a hand-cranked flip book. Today, the Mutoscope is probably most familiar to anyone who has visited Disney World or Disneyland, both of which have Mutoscopes in their arcades.

I was thinking about both devices and how they are so mechanically similar, so I thought I would try converting a Rolodex into a mini Mutoscope. It ended up being a pretty good fit after a few changes.

I started with the Rolodex model NSW 24C. Because this is a relatively old piece of office equipment, there was quite a bit of squeaking when turning the knob. So I disassembled the unit and used a bit of silicone grease in all of the places where plastic was rubbing against plastic.

You cannot use regular Rolodex cards with this device; you need to make your own. My cards (printed on card stock) measured 4″ x 2-1/2″. Instead of using the two raised “tracks” on the Rolodex spindle to loosely “hang” cards (a mechanism which works fine for storing contact information but not for flipping animated cards), I cut very thin slots in the tracks with a jeweler’s saw (size 3 blade). These cuts went lengthwise across the spindle, across the two tracks where regular Rolodex cards would usually go.

Although I put the spindle in a vice when cutting and tried to keep the jeweler’s saw as straight as possible, most of my cuts ended up angled for some reason. When I make my next Rolodex Mutoscope (I have three additional Rolodex units waiting in the wings), I’m going to find a way to ensure these cuts are straight. I was able to cut 29 slots — for 29 cards — in the plastic spindle; I probably could have cut a few more had the cuts been straight.

Before taking the plastic spindle out of the Rolodex, I put a piece of strong Velcro (the loop side) around the center, between the raised tracks. This wasn’t because I needed Velcro, but because the Velcro tape itself was so strong that it would hold the two pieces of the plastic spindle together when sawing the slots for the cards.

I attached a 1-1/2″ x 1-1/2″ corner brace with Gorilla Glue in the inside of the cover. This corner brace acts like your thumb when you are flipping through a flip book.

And that’s it! It’s a very simple device, and, as you can see from the video, it works pretty well.

Unlike pop songs, I don’t think I’ll ever run out of things to say in an animated film. Film allows for a broader range of subject matter than pop tunes. Film also requires many more disciplines to master; there’s always a new challenge lurking around the corner. I want to take the things I’ve learned from affecting audiences with The Simple Carnival and apply that toward visual, animated stories — stories that make audiences laugh, cry, and cheer. It’s going to be a while until I get there, but I look forward to sharing the results with you one day.

Unlike pop songs, I don’t think I’ll ever run out of things to say in an animated film. Film allows for a broader range of subject matter than pop tunes. Film also requires many more disciplines to master; there’s always a new challenge lurking around the corner. I want to take the things I’ve learned from affecting audiences with The Simple Carnival and apply that toward visual, animated stories — stories that make audiences laugh, cry, and cheer. It’s going to be a while until I get there, but I look forward to sharing the results with you one day.

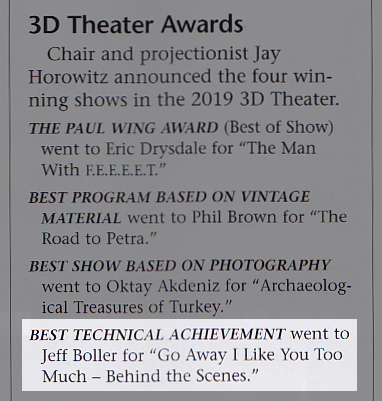

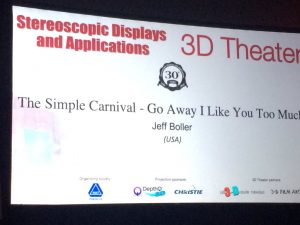

My 3D animated music video, “The Simple Carnival – Go Away I Like You Too Much” has been making the rounds on the film festival circuit. In February, I attended the

My 3D animated music video, “The Simple Carnival – Go Away I Like You Too Much” has been making the rounds on the film festival circuit. In February, I attended the

I’m pleased to announce that The Simple Carnival – Go Away I Like You Too Much

I’m pleased to announce that The Simple Carnival – Go Away I Like You Too Much